Oxygen Delignification & Bleaching

Sulphate pulp is brown in color as a result of the chemical treatment which dissolves the lignin. The bleaching plant transforms the color of the pulp by treating it in several stages with various chemicals including oxygen, peroxide and chlorine dioxide. As sulphite pulp is significantly lighter in color it can be used for newsprint (and other applications) without being bleached.

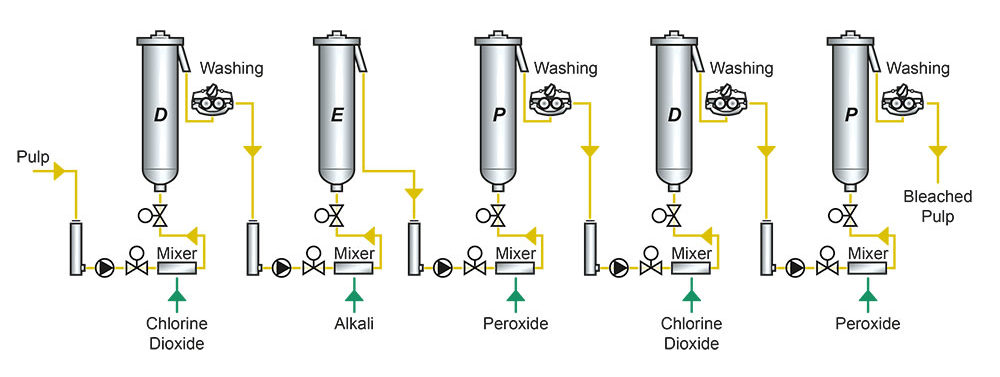

The number and order of stages used varies according to the intended use of the pulp as well as with the type of wood used. A bleaching sequence – a connection of bleaching stages – is described using internationally accepted terminology, where each stage or bleaching tower has a letter, indicating the chemical contained in it. Some of the most currently used bleaching stages are:

D = Chlorine dioxide stage

E = Extraction stage where chlorinated lignin is dissolved in alkali

O = Oxygen stage

P = Peroxide stage

Each bleaching stage basically consists of three parts: a mixer, a bleaching tower and a washer .

Oxygen delignification usually precedes the bleaching plant. This stage is generally placed between the screen room and the washing plant.

Most bleaching chemicals are bought ready to use and are delivered by road or rail. Chlorine dioxide, however, must be manufactured in the pulp mill, since it is too dangerous to transport. It is extremely poisonous and unstable and can explode at high concentrations.

Many bleaching chemicals are highly corrosive. Pipes, pumps and valves are therefore made of glass fiber-reinforced plastics, acid-proof high alloy steel or titanium.

Examples of NAF valves used in this process

- NAF Setball V-port ball sector valve, MC-pulp version – Control of MC-pulp

- NAF Setball V-port ball sector valve – Washing of black liquor, control of white liquor filtrate, chemically treated hot water to reactors, acid to feed pump, dropleg lower dilution, chlorine dioxide to D-stage (titanium), cavitation control in chlorine dioxide water (Z-trim)

- NAF Duball DL full bore ball valve – Chlorine dioxide pulp bleaching stage (titanium) , oxidized white liquor to cooler, sealing water, pressure control om MP-steam (Z-trim), MP-steam, acid to feed pump shutoff (Hastelloy)

- NAF Trunnball DL full bore ball valve – Chlorine dioxide pulp bleaching stage (titanium), reactor pressure relief, pulp in the alkaline extraction stage

- NAF Torex triple offset butterfly valve- Washing of black liquor, cooler backflush and discharge,

- NAF Turnex pneumatic actuator- For all control and on/off service on NAF rotary valve

- NAF Check- general service check valve service for pulp, steam, black liquor lines

- NAF Triball- drain valves, sampling valves