Recovery process

The process of chemical pulping would be impossible on a large scale without effective chemical recycling. Due to the low yield, there is a large amount of organic matter produced in the digester.

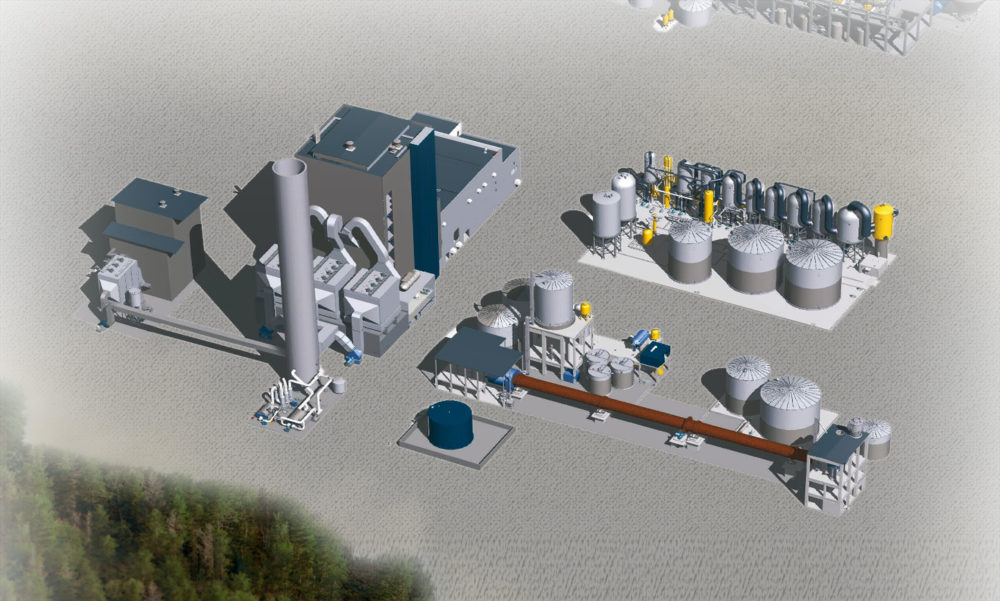

The best way to utilize this organic material is to burn it in a recovery boiler. A pulp mill is self-sufficient in energy and can often sell energy, either in the form of steam or as electricity. This recovery and power process consists of the following parts: evaporation, recovery boiler and white liquor preparation.